|

| May 19, 2020 | Volume 16 Issue 19 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Super steel project claims big breakthrough

Professor Huang Mingxin and PhD student Miss Liu Li with their new D&P super steel, which reaches an unprecedented high level of fracture resistance and excellent performance in ductility and strength. [Credit: ©The University of Hong Kong]

The Super Steel project led by Professor Huang Mingxin at the Department of Mechanical Engineering of the University of Hong Kong (HKU), with collaborators at the Lawrence Berkeley National Lab (LBNL), has made an important breakthrough in its new super D&P steel project by demonstrating greatly enhanced fracture resistance while maintaining super strength for advanced industrial applications. The material is called D&P steel because it is produced using a new "deformed and partitioned method." The steel is not the same as DP (dual-phase) steel.

The findings were published in Science on May 8, 2020, in the paper titled, "Making Ultrastrong Steel Tough by Grain-Boundary Delamination."*

Steel is a common alloy. Material scientists and engineers are continually seeking to develop next-generation steel materials that are easier to extend and elongate (ductility) into different forms and structures, higher in resistance to deformation (strength) and fracture (toughness), light in weight, and low in production cost.

The task has been difficult. The conventional view is that raising the performance of one metallic property, whether in strength, ductility, or toughness, will undermine one or more of the others. For example, an increase in strength will inevitably make the metal more brittle (known as the strength-toughness tradeoff) or less flexible to be extended or elongated into different shapes (strength-ductility tradeoff).

"In this latest breakthrough in super D&P steel, we attained an unprecedented strength-toughness combination which can address a major challenge in safety-critical industrial applications -- to attain an ultra-high fracture toughness so as to prevent catastrophic premature fracture of structural materials," said Huang. "The breakthrough also changes the conventional view that attaining high strength will be at the expense of deteriorating toughness, which invariably leads to the embrittlement of structural materials and greatly limits their application."

Earlier, the team had raised the D&P steel's strength-ductility performance significantly, so now the super D&P steel attains excellent performance in all three metallic properties at an unprecedented level.

Several patents in United States, EU, and China have been filed. The team has been liaising with industrial partners to generate prototypes of a high-strength bridge cable, bulletproof vest, and a car spring with the super steel for further testing.

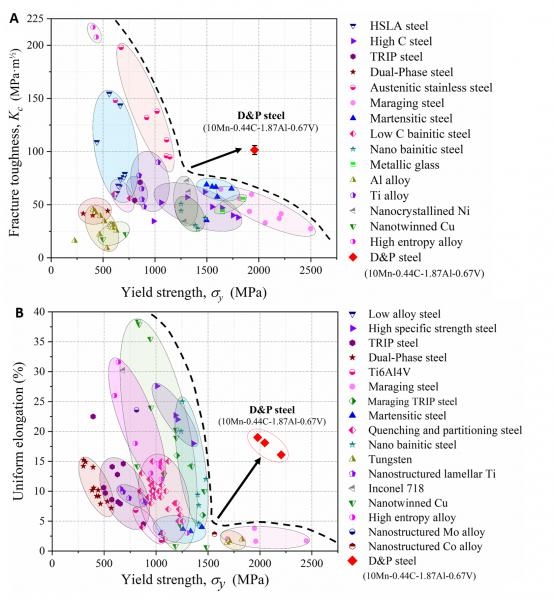

The latest advancement in D&P steel, made in collaboration with Professor Robert O. Ritchie's research team at the Lawrence Berkeley National Lab (LBNL) and UC Berkeley, results in a steel with a yield strength resistance against deformation of ~2GPa, a superior fracture toughness of 102 MPa · m½, and a good uniform elongation of 19 percent (Fig. A and Fig. B).

Currently, high-strength steel for bridge cables has a yield strength lower than 1.7 GPa and a fracture toughness lower than 65 MPa · m½; high-strength armored steel used in armored cars has a similar maximum strength/toughness combination. The toughness level that can be attained by the D&P steel is much higher than that of existing steel materials, while it maintains its super strength.

Steel piano wire, for instance, has a high strength ranging from 2.6 to 2.9 GPa to resist deformation and to keep the instrument in tune, but this is achieved at the expense of toughness. In turn, it is very brittle.

(A) Yield strength-toughness and (B) yield strength-uniform elongation of the present breakthrough D&P steel compared with other existing high-strength metallic materials. D&P steel demonstrated the best combination of yield strength, toughness, and uniform elongation. [Credit: ©The University of Hong Kong]

The team has also made an important scientific discovery in the structure of the super D&P steel. The super steel has a unique fracture feature in which multiple micro-cracks are formed below the main fracture surface through a novel "high-strength-induced multi-delamination" toughening mechanism. These micro-cracks can effectively absorb energy from externally applied forces, resulting in the steel's much higher toughness resistance compared to existing steel materials.

Meanwhile, the cost of raw materials of the D&P steel is only 20 percent of the maraging steel currently used in aerospace (e.g., Grade 300, whose yield strength and fracture initiation toughness are 1.8 GPa and 70 MPa · m½, respectively).

"D&P steel has other advantages such as simple industrial processing and low raw materials cost," said Li Liu, the first author of the journal article and a PhD student supervised by Huang. "It can be produced by conventional rolling and annealing processes. As such, no complex fabrication routes and special equipment are required."

"We have made a big step closer to industrializing the novel super steel. It demonstrates a great potential to be used in various applications including superior bulletproof vests, bridge cables, lightweight automobile and military vehicles, aerospace, and high-strength bolts and nuts in the construction industry," said Huang.

*Editor's Note: Please see the referenced paper for the technical description and steel "recipe."

Source: The University of Hong Kong

Published May 2020

Rate this article

View our terms of use and privacy policy